A note about terminology

Handgun safes must meet four criteria in order to satisfy the needs of gun owners who keep handguns for defensive purposes. First, the device must be small enough to make placement easy. Second, the device must allow for quick access. Third, the controls intervening between the user and the locking mechanism must be minimally complex to operate. Fourth, the device must prevent unauthorized access.

Regardless of what a manufacturer calls a handgun safe—“gun vault,” “lock box,” “pistol box,” “pistol safe” or “portable case”—the above design criteria must apply if the device is to meet the needs of gun owners. Every device examined on this website, accept for gun locks, serves the same function and is therefore a handgun safe. Though California law refers to these devices as “lock boxes,” lock box is a synonym for handgun safe in the discussions on this site.

lock boxes

Lock boxes are designed to allow ready access to firearms kept for defensive purposes, while keeping firearms inaccessible to unauthorized individuals. These devices are not intended to provide fire protection, humidity control, or defense against brute-force attack with large hand tools like pry bars and power tools. Lock boxes can be divided into two kinds:

Devices with mechanical pushbutton locks.

Lock boxes with mechanical pushbutton locks are typically

fitted with a 5-button Simplex lock. (See The Simplex Lock for details.) Occasionally, a manufacturer may use another type of pushbutton lock, though it will have to allow for a minimum of 1,000 possible combinations in order for the lock box to be in compliance with California's Firearms Safety Device Standards.

Devices with electronic locking mechanisms.

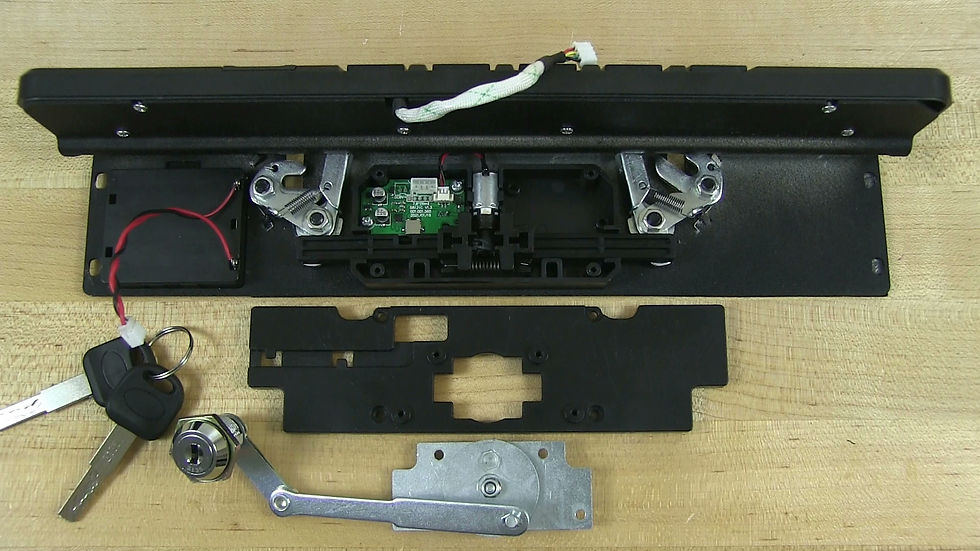

Electronic lock boxes typically have five components:

1) A container, including the box, door, hinges, and keypad

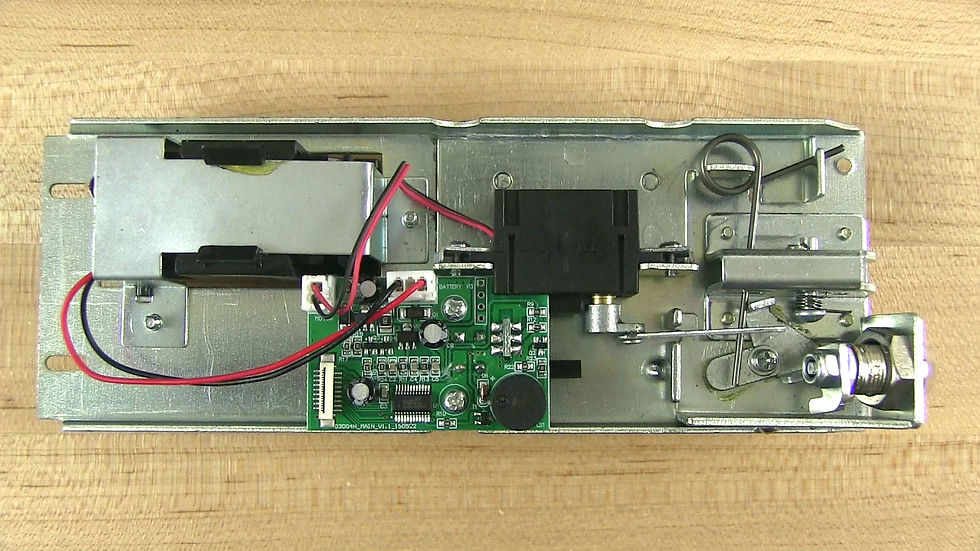

2) Mechanical components of the locking mechanism proper

3) Electronic components of the locking mechanism proper

4) A processor with on-board programming

5) A mechanical bypass lock actuated by a key

Not every electronic lock box has all five of these components, but the majority of them do. Some electronic lock boxes have no keyed bypass locks. These devices will have an exposed pair of contact points for applying a 9V battery should the installed batteries fail. Lock boxes having a mechanical pushbutton lock typically do not have a bypass lock.

Locking mechanisms

Lock boxes with electronics can be divided into four groups based on the most commonly used mechanisms installed in them. These are 1) motorized boltwork, 2) motorized latches, 3) spring-release latches, and 4) solenoid-locked boltwork.

1) Motorized boltwork:

As the name implies, a motor is used in these mechanisms to draw the boltwork back and return the bolts to the locked position. This arrangement allows the boltwork to be locked in place by the motor’s gearing when the safe is closed. Though these mechanisms are relatively secure, motorized boltwork mechanisms are slow to actuate the bolts, and don’t offer the quick-release response people want in a handgun safe. Few handgun safes have this kind of mechanism installed in them.

This generic mechanism was installed in the Bulldog Vaults BD4010, no longer available.

This generic mechanism was installed in the Bulldog Vaults BD3000, no longer available.

This bolt mechanism is installed in the Viking Safe VS-51KS.

This bolt mechanism is installed in the Verifi Smart Safe line.

2) Motorized latches:

Motorized latch mechanisms are diverse. The distinguishing characteristic of these mechanisms is that a motor rotates a fitting designed to nudge or push the latch’s hardware into the open position, releasing the door. The latching assembly is not held in place by the motor’s gearing, and is designed to move independently of the motor. Motorized latch mechanisms can be made secure if a manufacturer eliminates extraneous holes in a device allowing access to the mechanical components of the mechanism.

Paragon Safe stopped importing this handgun safe into the U.S. some time in 2016.

Was previously the Stack-On PC-900.

This motorized latching device is used in many generic boxes imported into the U.S., including boxes sold under the Cabelas brand name.

3) Spring-release latches:

Spring-release latching mechanisms are extremely diverse, though any given design will rely on one of two methods of actuation, Release Wire or Contour Locking. (No official names exist for these actuation methods, and the two designations used here are used for convenience.)

Release Wire

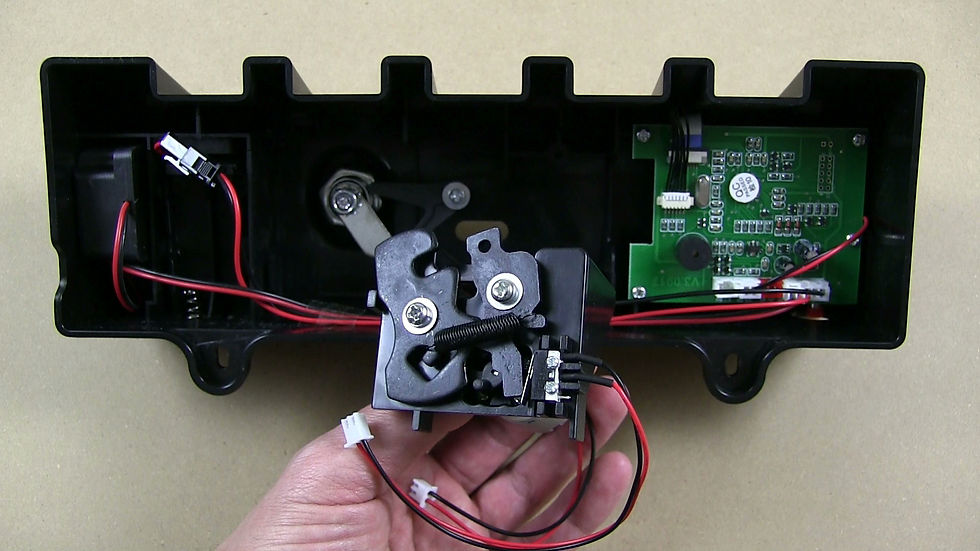

The Release Wire assembly involves two pieces of hardware, a latch and a release, each mounted vertically on either side of a simple framework. Both pieces rotate in place. The latch piece has a spring attached to it to keep the latch under tension. The latch also has a pin passing through it that slips into a notch in the profile of the release. Another notch cut into the release allows a long sprung wire (the Release Wire) to pass through the assembly, where it rests against the release when the latch is locked.

To release the latch, a motor is used to draw back the Release Wire resting against the release. This rotates the release until is slips off of the pin attached to the latch, and the spring keeping tension on the latch throws the latch open.

This is one the most widely used latching mechanisms, based on a mechanism developed for GunVault products.

This basic latching mechanism is used in almost all of GunVault's handgun safes.

Contour Locking

The Contour-Locking latch assembly involves two pieces of hardware, a latch and a release, mounted side-by-side on a framework. Both pieces rotate. A spring stretches between them. The latch and release are designed with profiles that allow the pieces to meet edge-to-edge in a stable position when locked. To release the latch, a motor is used to pull the release from its stable position, and the spring stretching between the two pieces throws the latch.

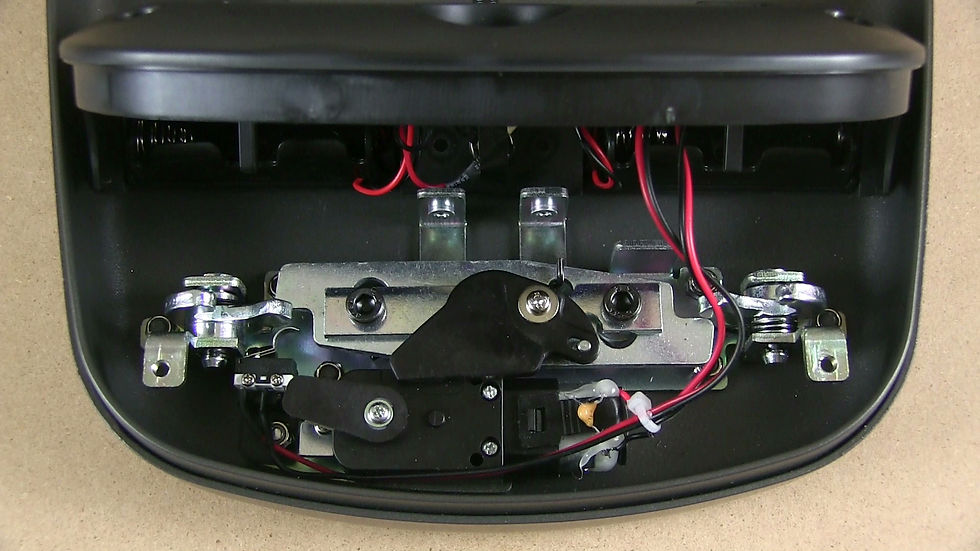

Dual Contour Locking

Contour-locking assemblies may be designed to work with a single latch or with dual latches. Below are two examples of dual contour-locking mechanisms.

4) Solenoid-locked boltwork:

This is the most common locking mechanism found in small personal safes, though not necessarily in lock boxes. In these mechanisms, a solenoid pin is used as a device to prevent the safe’s boltwork from being retracted until someone enters a correct access code. Depending on the strength of the spring in a solenoid, its magnetic pin may be bounced by shaking or dropping a safe that isn’t bolted down. In an effort to design solenoid-locked safes resistant to being bounced or shaken open, designers have arranged internal components in different ways, with solenoids oriented horizontally or upside down.

Old-styled solenoid, used for many years on small personal safes

Solenoid with housing and integrated lever

This style of solenoid is becoming the preferred design in small personal safes.

BIOMETRICS

The most important thing to understand about biometric technology is that a fingerprint reader is not a locking mechanism. The fingerprint reader is another part of a safe’s controls and serves the same function as a keypad. The reason for incorporating biometrics into the controls of a safe is that a fingerprint reader provides a uniquely user-specific form of access code.

However, if a fingerprint reader is going to add any level of security to a safe, the same design considerations pertaining to any handgun safe must be addressed. Extraneous holes in a safe that allow access to the mechanical components of a locking mechanism will undermine security, regardless of the biometrics. Extraneous holes allowing access to the controls for entering and deleting fingerprints will also undermine all security.

As discussed in Errors In Engineering, programming sequences for biometric controls pose yet another security consideration. Industrial designers in years past have allowed consumer-grade biometric systems to behave as though a fingerprint were registered before a user was enrolled. This has left safes ready to open for any random fingerprint out of the box. The user of a poorly designed safe who attempts to enroll a fingerprint improperly, and who thus leaves the safe accessible to any random scan, will be unaware that a firearm is also accessible. Companies are now recognizing the need to prevent this form of user error in their products.